TECHNICAL STUDY

EMS cots are subjected to weight that may not always be coaxial with their center of gravity, especially during the course of patient transfer from emergency scene to cot or cot to bedside. Such offset loads create a mechanical moment about the structure of the cot. In instances in which this resulting moment exceeds the resistance of the cot to tip, stability is lost. Loss of cot stability is dangerous to patients and EMS professionals. The objective of this study was to determine the resistance to tip of commercially-available EMS powered cots based on offset patient placement at multiple bed heights.

Methods

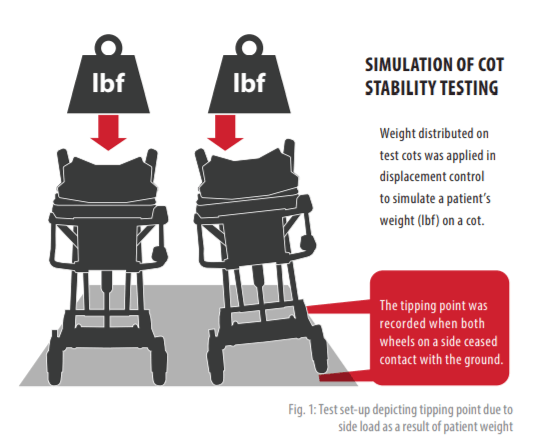

An EMS cot was placed at three bed heights often utilized during an emergency service call: low bed height, patient seated height, and transport height. For each height, a quasi-static load was applied in displacement control on one side of the cot via a custom free-pulley system. The origin of the load vector was evenly distributed about the seat panel with the direction simulating a patient seated on the edge of the cot with feet hanging to the side. A load cell was placed in line with the direction of applied load, and the resultant force in which both opposite side wheels ceased contact with the ground was considered the tipping point of the cot (Figure 1a). A higher achieved load was indicative of greater resistance to tip. Two emergency cots were tested at the same height as measured from the floor to seat panel: the FERNO POWER X1 Ambulance Cot (Wilmington, OH), which features TipRESIST™ Advanced Stability Technology, and the Stryker® Power-PRO™ XT (Portage, MI). Runs were performed in triplicate and data was averaged, with statistical analyses reported at α = 0.05.

Results and Discussion

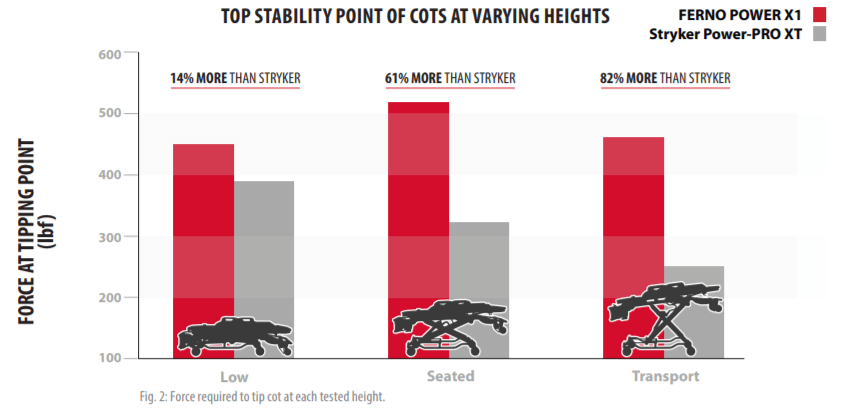

Resistance to tip was exceeded in all scenarios at loads below the full weight capacity of the cots, which was 700 lbf (3114 N), respectively( Figure 2). There was a 14% increase in the resistance to tip of the POWER X1 (447 ± 20 lbf [1988 ± 89 N]) as compared to the Power-PRO XT (392 ± 3 lbf [1744 ± 13 N]) cot at low bed position (p = 0.04). At patient seated height position, the POWER X1 cot was 61% more resistant to tip as compared to the Power-PRO XT (517 ± 51 lbf [2300 ± 227 N] versus 322 ± 3 lbf [1432 ± 13 N], p = 0.02). At transport height position, the POWER X1 was 82% more resistant to tip as compared to the Power-PRO XT (457 ± 37 lbf [2033 ± 165 N] versus 252 ± 10 lbf [1121 ± 44 N], p << 0.05). There was a nonlinear correlation between cot bed height and resistance to tip for the POWER X1 cot; a parabolic relationship existed in which the patient seated height displayed the greatest stability. This was attributed to the fact that at the fully-collapsed low bed height, the cot is fully supported by its structure, which results in greater rigidity. At the fully-extended transport height, the cot’s x-frame supported the cot and resulted in greater rigidity. Greater rigidity in both of these instances resulted in decreased stability compared to the seated position, but stability was still superior to that of the Power-PRO XT. At seated height, the structural flexibility of the cot absorbed the applied patient weight prior to tipping and provided a more stable cot. The Power-PRO XT was found to be more rigid than the POWER X1 cot since there was an extremely high negative correlation between cot bed height and resistance to tip; as bed height increased, resistance to tip decreased (r = – 1). The lack of flexibility contributed to less stability for the Power-PRO XT.

Conclusion

EMS cot stability is important during the transfer of patients. Loss of stability can lead to injury to EMS professionals or further patient injury. The resistance to tip due to applied offset loading, which can often occur with a seated patient or a patient being transferred to the bedside, was assessed in this study. Significant differences existed between the POWER X1 and Power-PRO XT cots with regard to the force required to tip. Across all three tested bed heights, the POWER X1, which features TipRESIST Advanced Stability Technology, provided 52% greater stability on average and 82% more at transport height than the Power-PRO XT.Key Definitions

“N”=“Newton”— the standard unit of force in the International System of Units.LBF— The pound-force (symbol: lbf, or lbf ) is a unit of force.

For purposes of this white paper, LBF represents “simulated patient weight” and “N” is used as a unit of measurement during stability testing.